Coutact Us

Whatsapp:+8618075108880

Email:info@ec-fibercable.com

Time:2023-02-23 10:43:56

Features of indoor optical cables,Optical fibers have become the standard for high-speed data transmission in many applications, ranging from telecommunications and networking to industrial and medical systems. These fibers are used to transmit data over long distances, but they are also used in indoor applications, such as data centers, offices, and homes. In indoor settings, optical fibers need to be flexible, easy to install, and resistant to environmental factors, such as bending, crushing, moisture, and temperature changes. Indoor optical cables are designed to meet these requirements and offer many features that make them suitable for indoor use. In this article, we will discuss the features of indoor optical cables in detail.

Construction

Indoor optical cables are constructed with a central optical fiber core, which is surrounded by a protective cladding and coated with a buffer layer. The cladding provides protection against bending and crushing, while the buffer layer protects the fiber from moisture, dust, and other environmental factors. The buffer layer is usually made of materials like PVC, LSZH (low-smoke zero-halogen), or TPE (thermoplastic elastomer), depending on the application.

Indoor optical cables can be designed with various constructions, such as simplex, duplex, or multi-fiber configurations. Simplex cables contain a single fiber, while duplex cables contain two fibers, and multi-fiber cables contain multiple fibers. The fibers can be bundled together in tight buffer or loose tube designs, depending on the application.

Flexibility

Indoor optical cables need to be flexible to allow for easy installation and routing around obstacles. Tight buffer designs provide better flexibility and are suitable for short-distance applications, such as LAN (local area network) connections in offices or homes. Loose tube designs are more suitable for longer distances, such as backbone connections in data centers or campuses, as they provide better protection against external factors.

Bend Radius

Indoor optical cables need to have a minimum bend radius, which is the minimum radius at which the cable can be bent without damaging the fiber. The bend radius depends on the cable construction and the fiber type, but typically ranges from 10mm to 25mm for tight buffer designs and 20mm to 50mm for loose tube designs. Cables with a smaller bend radius provide better flexibility but may be more susceptible to bending losses, while cables with a larger bend radius provide better protection but may be less flexible.

Connector Types

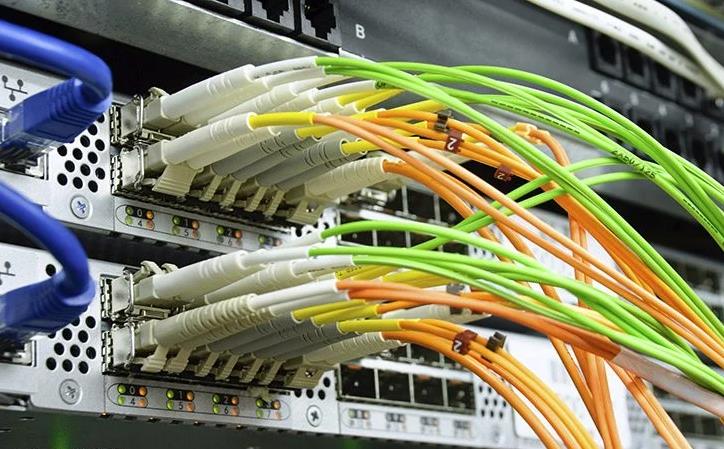

Indoor optical cables are terminated with connectors that allow for easy connection to other devices, such as switches, routers, or patch panels. The most common connector types used in indoor applications are LC (Lucent Connector) and SC (Subscriber Connector). LC connectors are smaller and provide higher density connections, while SC connectors are more robust and suitable for harsh environments.

Fire Resistance

Indoor optical cables need to be fire-resistant to meet building codes and safety requirements. LSZH (low-smoke zero-halogen) cables are designed to minimize smoke and toxic gas emissions in case of fire, making them suitable for indoor applications. PVC (polyvinyl chloride) cables are not recommended for indoor use because they release toxic gases when burned.

Moisture Resistance

Indoor optical cables need to be resistant to moisture, which can damage the fibers and reduce their performance. Cables with LSZH or TPE (thermoplastic elastomer) jackets provide better moisture resistance and are suitable for indoor applications. Cables with PVC jackets are not recommended for outdoor or harsh environments because they absorb moisture and can become brittle over time.

Temperature Range

Indoor optical cables need to be able to withstand a wide range of temperatures, from -20°C to 70°C, depending on the application. The temperature range depends on the cable construction and the materials used for the jacket and coating.