Coutact Us

Whatsapp:+8618075108880

Email:info@ec-fibercable.com

Time:2023-02-10 09:10:26

With the increasing trend of social electricity consumption, higher requirements are put forward for the performance of electric power communication network. Only by ensuring good communication condition, can the safety and stability of electric power system be enhanced and more quality power supply service be provided to users. The application of ADSS optical cable communication in practice can effectively expand transmission capacity, ensure the high efficiency of signal transmission, is the key to promote sustainable development of the electric power industry in our country, and conforms to the requirements of the construction of smart grid. Under the influence of external environment, human factors and optical cable performance factors, ADSS optical cable will have many problems, which will cause line failure and even lead to serious power safety accidents, which is not conducive to the continuous promotion of electric power work. Therefore, the effective management and maintenance of ADSS optical cable should be strengthened to reduce the operating risk of optical cable. We should combine the operation characteristics and requirements of the communication network, formulate specific application schemes to prevent unexpected problems.

First, ADSS cable overview

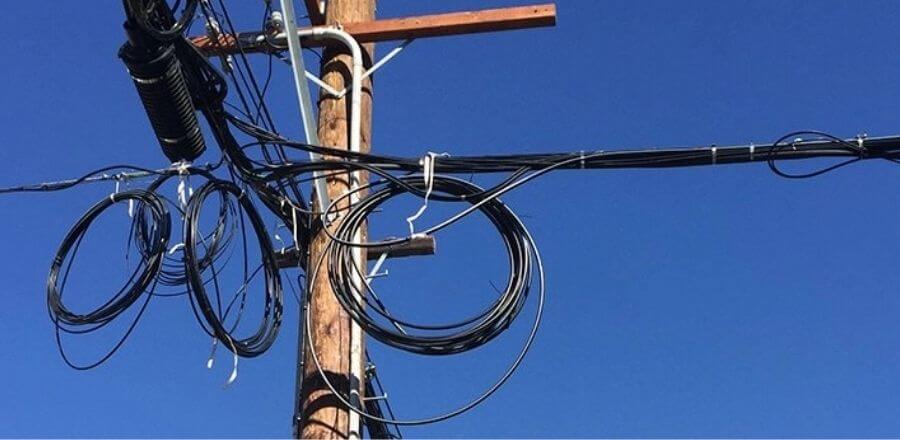

When installing ADSS cable, a variety of factors need to be considered, including sag, distance and environmental conditions, to determine the cable usage and erection method. The mechanical strength of ADSS cable is tested to ensure that it has good performance. In overhead power lines, ADSS optical cable is widely used, which can meet the requirements of tower erection, has good economy, and can reduce the construction cost of power engineering [1]. The application of ADSS cable is more, usually suitable for 220kV line, line bearing capacity and suspension line is more fixed, can avoid the greater impact on the cable.

Two, ADSS cable application process problems

1. Electric corrosion

Long-term exposure to the external environment, will lead to an increase in soluble salts on the surface of the optical cable, and will be affected by dust, when there is a semi-conductive dirty layer, will make the surface resistance of the optical cable decline, if there is a large induction potential around, it will cause leakage current. Dry strip arc is the main cause of electrical corrosion. When electrical corrosion occurs, ADSS cable will be destroyed, which affects the good communication effect and also has a big security risk. Failure to control the distance from the ADSS cable when applying the shockproof whip can also cause corona discharge conditions, which can also lead to electrical corrosion conditions.

2. Mechanical properties are damaged

The mechanical properties will affect the stress characteristics and running conditions of the optical cable, and the failure to make a reasonable choice in the selection of ADSS optical cable is the main cause of the problems in the subsequent use. Failure to analyze and evaluate the stress data of optical cable from the perspective of static mechanics leads to uneven stress during its use and serious damage during stretching [2]. It is necessary to use relevant professional software to calculate the tensile condition and arc sag. However, due to the influence of various external factors, the calculation process is very complicated, and it is difficult to obtain reliable data. Therefore, the protection effect on the mechanical properties of ADSS cable is not good.

3. Dynamic change

The electrical condition is not invariable, but presents the characteristic of dynamic change, which also has a great negative impact on the application of ADSS cable. The calculation is usually carried out based on static changes, and the lack of analysis on the performance of optical cable under dynamic changes is easy to cause the fault of optical cable, which is not conducive to the operation of communication network. For electromagnetic state analysis, in addition to clear the distance of ADSS cable, should also pay attention to its hanging point, but in practice, the analysis work is often lack of dynamic, increase the difficulty of calculation processing.

4. Environmental factors

Environmental factors are the main factors affecting the application performance of ADSS optical cable, especially when there is a large difference in the external temperature, it will also lead to changes in the performance of ADSS optical cable. It is often necessary to analyze the influence characteristics by means of simulation experiments, in order to obtain the changes in the performance of optical cable under different temperatures. The use of ADSS cable will also be affected by strong wind. If the wind speed is too high or too fast, the construction and application will be affected [3]. In winter, there is a lot of snow and ice cover, so that the optical cable load increases, there will be a big security risks.

Third, ADSS optical cable application problem solution

1, prevent electric corrosion

Reasonable selection of cable hanging points can reduce the probability of electrical corrosion and enhance the running quality of power communication network. It is necessary to scientifically plan the line, obtain and evaluate the distribution characteristics and intensity of the inductive electric field, so as to ensure the scientific and feasible location of the hanging point and reduce the impact on ADSS cable. The tip discharge can be controlled effectively by means of discharge corona ring. The value of corona initiation voltage is significantly increased, so the occurrence of corona discharge can be controlled [4]. In practice, we should analyze the problems caused by different factors, so as to clarify the specific characteristics of the influence, so as to take effective prevention and control measures.

2, reasonable choice of optical cable

The reasonable selection of ADSS cable can also improve the reliability of the cable operation and reduce the failure rate of the line. All kinds of factors affecting ADSS cable should be comprehensively considered, with the help of advanced computer software simulation and calculation, taking into account the influence of mechanical properties, dynamic factors and weather factors and other parameters, to ensure that in the field erection can develop a feasible scheme. Enhance communication with relevant manufacturers, implement comprehensive control over the performance of optical cable, and prevent more problems in application [5]. The application of PE outer sheath material in practice is more, which can effectively improve the electrical trace resistance performance of optical cable and prolong the service life of optical cable.

3. Strengthen construction control

During the construction process, the quality of ADSS cable erection should be controlled, the layout of the erection line should be clear, and the surrounding trees, buildings and pipelines should be investigated in advance, so as to reduce the influence of external factors on the operation of ADSS cable and prevent the failure of ADSS cable caused by environmental problems. In the construction should do a good job of ADSS cable protection, especially to the surface of the timely cleaning, to prevent pollution problems caused by serious failures. Strengthen the overall supervision on the construction site to ensure that the installation strictly follow the relevant technical standards and specifications, to prevent improper operation caused by failure.

4. Good operation and maintenance

In the operation of ADSS optical cable should develop a perfect maintenance plan, in view of the hidden problems for comprehensive investigation and control, to promote the extension of service life. Make reasonable operation and maintenance plans according to the actual operation requirements of power lines to ensure that the performance and safety of optical cables meet the requirements [6]. The maintenance process should be reasonably optimized, and a perfect system should be established to prevent formalized problems in maintenance and operation. Use special maintenance tools to carry out inspection, especially after bad weather should increase the maintenance efforts, to prevent serious damage under the influence of external environmental factors.

Four. Conclusion

ADSS optical cable has obvious advantages in performance, so it has become a common type of optical cable in the current power communication system, which can guarantee good transmission quality. However, due to the effects of electrical corrosion, mechanical property damage, dynamic change and environmental factors in the application of ADSS cable, the stability and security of the communication network are also reduced. Therefore, the application level of ADSS optical cable should be improved gradually and its performance should be comprehensively optimized by preventing electrical corrosion, rationally selecting optical cable, strengthening construction control and doing a good job in operation and maintenance.