Coutact Us

Whatsapp:+8618075108880

Email:info@ec-fibercable.com

Time:2023-02-08 11:53:18

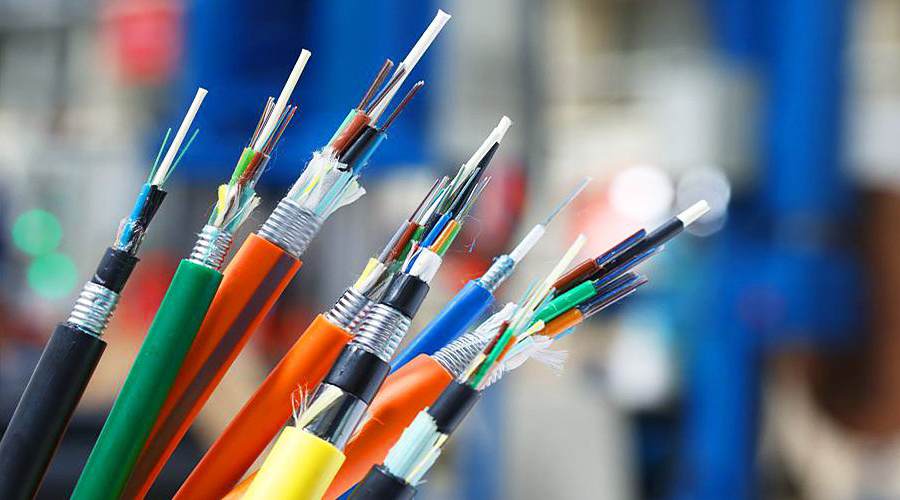

There are many materials used in indoor fiber optic cables, each of which can be changed in many different formulations. The main components of indoor optical cables include optical fibers, strength members and jacket materials.

There are many materials used in indoor fiber optic cables, each of which can be changed in many different formulations. The main components of indoor optical cables include optical fibers, strength members and jacket materials.

Optical fibers involve single-mode and multi-mode, and various fibers may appear in indoor optical cables. Of course, the development trend is that optical fibers with bending resistance, stable geometric dimensions and high mechanical strength are more suitable for the requirements of indoor optical cables.

There are many kinds of reinforcements, non-metal reinforcements are the mainstream, and aramid yarn is the most common reinforcement material. Of course, other reinforcement materials, such as reinforcement materials, such as PBO, high-strength polyethylene fiber, glass fiber, polyester yarn, GFRP, KFRP, indoor optical cable performance requirements, structural size requirements, user selection and cost prices and other factors, may Steel wires and rebar materials of different braided shapes will appear.

Indoor optical cables have requirements on the strength, tensile strength, low smoke and flame retardant, high temperature resistance, environmental protection, easy processing, and protection of optical fibers of reinforced materials.

Polyvinyl chloride is the most commonly used sheath material (PVC), low-smoke halogen-free flame retardant polyolefin (LSZH), halogen-containing flame retardant polyolefin (flame retardant polyethylene) (ZRPO), nylon (PA) polyurethane elastomer ( TPU) composite materials, composite materials, that is, a mixture of several materials, also appear.

Future sheath materials require low smoke and halogen free, high flame retardant, low shrinkage, low temperature resistance, high temperature resistance, easy processing, environmental protection, high strength, crack resistance, suitable hardness, anti-aging, color and color uniformity, mechanical and physical properties, Smell, feel and low cost price, even anti-rat bite, corrosion resistance, sunlight resistance, bending resistance, thin wall processing, etc.

The variation or instability of material batches is fatal to the production of indoor optical cables, and almost accounts for more than 60% of the quality problems of indoor optical cables due to the quality problems of materials. This places higher demands on material suppliers. At the same time, material engineers need to develop various materials that meet the requirements of indoor optical cables as soon as possible, and the material properties are stable.

EC Cable reminds that the development of raw materials also determines the development of indoor optical cables, and its role cannot be ignored. Indoor optical cables are highly dependent on raw materials, and have high requirements for materials. With the selection of users and the market, the requirements for raw materials also change at any time. Develop original adaptability, stability, reliability, variety and low cost.

EC Cable focuses on the research and development and sales of optical fiber communication products. Optical communication products include standard product optical cables, optical fiber jumpers Cables, mpo/mtp data centers, optical fiber distribution frames, etc., at EC Cable you can buy all optical communication products in one stop.